Motorheads are always in search of ways for more power or less

weight. When it comes to removing weight from your Mustang, taking

it off the front end of the car is preferable to removing it from

elsewhere. With this in mind, I decided to remove some weight

from the front of my 93 LX coupe using a tubular front-end

system and switching to manual steering. Of course there were

some "snags" encountered along the way but if you follow along

with my install, hopefully I can save you some aggravation.

With the popularity of the Fox Mustang being at an all time high,

there are many front suspension systems available. But which one

should you choose for your car? My decision was based on the

purpose of the car, in my case a street/strip fun car, and as

there are many front suspension systems available. But which one

should you choose for your car? My decision was based on the

purpose of the car, in my case a street/strip fun car, and as

such I looked at a few different companies before settling on

the kit from

Unlimited Performance. You should be aware that

not all tubular K-members are alike. Some move the control arm

mounting points forward as compared to stock which might

benefit the road racer. Others move the engine mounting points

toward the rear for redistribution of weight while others

such I looked at a few different companies before settling on

the kit from

Unlimited Performance. You should be aware that

not all tubular K-members are alike. Some move the control arm

mounting points forward as compared to stock which might

benefit the road racer. Others move the engine mounting points

toward the rear for redistribution of weight while others

have no provisions for motor mounts all together as they

are intended to be used with a motor plate for securing

the engine. And finally, some K-members do not have

provisions for stock style front springs since they are to

be used only with coilovers. The Unlimited Performance

K-member retains all stock mounting locations for springs,

steering rack, motor mounts and control arms. It can also

be used with coilovers as well as factory or aftermarket

control arms. This K-member is constructed of chromemoly

tubing which makes it even lighter than comparable units

have no provisions for motor mounts all together as they

are intended to be used with a motor plate for securing

the engine. And finally, some K-members do not have

provisions for stock style front springs since they are to

be used only with coilovers. The Unlimited Performance

K-member retains all stock mounting locations for springs,

steering rack, motor mounts and control arms. It can also

be used with coilovers as well as factory or aftermarket

control arms. This K-member is constructed of chromemoly

tubing which makes it even lighter than comparable units

made of mild steel. The finish is a nice black powder

coating for durability. The tubular control arms are also

of chromemoly construction with the same gloss black powder

coated finish. The Unlimited Performance coilovers

feature aluminum sleeves and adjustable mounts in a blue

anodized finish, springs and a top mount with a

Torrington roller bearing. The supplied control arm bushings are urethane

and come with chromemoly bushing sleeves. Ride height is fully

adjustable by screwing in or out on the spring perch.

made of mild steel. The finish is a nice black powder

coating for durability. The tubular control arms are also

of chromemoly construction with the same gloss black powder

coated finish. The Unlimited Performance coilovers

feature aluminum sleeves and adjustable mounts in a blue

anodized finish, springs and a top mount with a

Torrington roller bearing. The supplied control arm bushings are urethane

and come with chromemoly bushing sleeves. Ride height is fully

adjustable by screwing in or out on the spring perch.

For the Steering components,

Flaming River's quick ratio manual

steering rack and solid steering shaft were selected. I also used

Flaming River's outer tie rod ends. Flaming River has different

solid steering shafts as well as tie rods depending on whether you

steering rack and solid steering shaft were selected. I also used

Flaming River's outer tie rod ends. Flaming River has different

solid steering shafts as well as tie rods depending on whether you

are converting a power or manual rack car to begin with. The rack

I selected features 3.33 turns lock to lock and a 15:1 ratio. The

rack comes with new steering rack bushings; these would not work

with the Unlimited Performance K-member however. The K-member

are converting a power or manual rack car to begin with. The rack

I selected features 3.33 turns lock to lock and a 15:1 ratio. The

rack comes with new steering rack bushings; these would not work

with the Unlimited Performance K-member however. The K-member

utilizes an older style Fox bushing which had to be obtained

locally. This style bushing does away with the inner metal sleeve

and slides onto the rack mount with one in behind and another in

front of the rack. The 93 Mustang stock hardware would also not

work and required a trip to the hardware store to secure a couple

grade 8, 1/2" coarse thread bolts of about 1" length and

corresponding washers. Due to the powder coated K-member a tap

was required to clean out the holes before the bolts to the

steering rack could go through.

utilizes an older style Fox bushing which had to be obtained

locally. This style bushing does away with the inner metal sleeve

and slides onto the rack mount with one in behind and another in

front of the rack. The 93 Mustang stock hardware would also not

work and required a trip to the hardware store to secure a couple

grade 8, 1/2" coarse thread bolts of about 1" length and

corresponding washers. Due to the powder coated K-member a tap

was required to clean out the holes before the bolts to the

steering rack could go through.

There were a few other items involved in this front-end makeover

in order to complete the installation. When such a system is

installed it will be required that you use aftermarket

caster/camber plates in order to maintain front-end alignment.

Maximum Motorsports CC plates were used for this conversion. The

coilovers will work with stock style struts as well as

Koni or

Lakewood struts. The car used for the installation already has

Lakewood 70/30 front struts and these were retained. It is

important to note that these struts have a dust cover that is

spot welded on and must be removed before the coilover sleeves

and springs will go on the strut. Care must be exercised when

attempting to remove this dust cover, as the spot welds need to

be drilled out. The trick is to not go completely through the

welds with the drill bit for fear of drilling into the strut

installed it will be required that you use aftermarket

caster/camber plates in order to maintain front-end alignment.

Maximum Motorsports CC plates were used for this conversion. The

coilovers will work with stock style struts as well as

Koni or

Lakewood struts. The car used for the installation already has

Lakewood 70/30 front struts and these were retained. It is

important to note that these struts have a dust cover that is

spot welded on and must be removed before the coilover sleeves

and springs will go on the strut. Care must be exercised when

attempting to remove this dust cover, as the spot welds need to

be drilled out. The trick is to not go completely through the

welds with the drill bit for fear of drilling into the strut

itself thereby rendering it useless. I did this during the

install and heard an awful "Pssst" sound as I penetrated through

the strut. Another trip to the store was required to buy another

strut, so be careful when doing this. A tip that may help is to

drill part way through the spot weld then use a drift punch and

hammer to knock the dust cover loose as you hold the strut in a

bench vice. I was able to remove the dust covers without any

damage to the strut using this method. This was followed by

blowing the top of the strut off with compressed air in order to

remove any metal fillings that may have collected around the

strut shaft.

itself thereby rendering it useless. I did this during the

install and heard an awful "Pssst" sound as I penetrated through

the strut. Another trip to the store was required to buy another

strut, so be careful when doing this. A tip that may help is to

drill part way through the spot weld then use a drift punch and

hammer to knock the dust cover loose as you hold the strut in a

bench vice. I was able to remove the dust covers without any

damage to the strut using this method. This was followed by

blowing the top of the strut off with compressed air in order to

remove any metal fillings that may have collected around the

strut shaft.

Before proceeding with the new parts I elected to purchase new

control arm bolts and nuts from the local

Ford dealership. These

carry part number N804591-S100 and N800237-S427 respectively.

After obtaining these bolts it turns out they would not slide

through the control arm bushing sleeves as supplied by Unlimited

Performance. The inside diameter of these sleeves measured .008"

undersize according to my dial calipers. A phone call later to

Unlimited Performance Products verified that indeed they had sent

out a few undersize sleeves by mistake and new sleeves were on

the way. These new sleeves were correctly sized and the bolts

slid right through. The ends were a bit rough and a little

filling was necessary to clean them up. The dust boots for the

greasable ball joints were then installed on the tubular control

arms, as were the zerk fittings. This car had previously been

changed over to 5-lug front rotors using the Motorsport M2300-C

kit. While they were off the car during this front suspension

redo, it was thought that the addition of NHRA legal long studs

would be a good idea. This brings up yet another minor problem.

The Ford studs are 1/2" and feature a .560" knurl while all

aftermarket long studs in this size knurl are 7/16". This makes

it necessary to open up the holes in the rotor to fit the more

common .615" knurl stud. For this purpose a set of Moroso 3" long

studs of the correct 1/2" diameter and proper .615" knurl were

utilized. The rotor holes were opened up by a local machine shop

using a self-centering bit. Also of note is the fact that the

holes are not opened all the way to .615" because an interference

fit is needed. Getting the holes opened up this way ensures that

the holes are centered and eliminates possible wheel balance

problems which can happen if you enlarge the holes by hand.

It's now time to get greasy! The engine in my car was removed and

this made the job a bit easier. If you still have your engine in

the car it will be necessary to lift the motor and its mounts

slightly in order to remove the stock K-member. Before proceeding

with the K-member removal, you will need to remove the stock

struts, spindles, brakes, caster/camber plates, steering rack and

control arms. Take care to avoid injury when removing the front

springs! They are under tremendous pressure and must be handled

carefully and safely. I use a floor jack under the control arm

and with the top strut mount loose slowly lower the floor jack.

This allows the spring to extend to the maximum and then I use a

pry bar to pop it out while standing away from the wheel well

area. Disconnect the tie rods and remove the spindles and don't

forget the sway bar as well. Now you can remove the K-member

bolts (4 per side) and drop the K-member using a floor jack.

Again, be careful, as this piece is heavy. I left my stock

control arms attached to the K-member since I was switching to

the aftermarket units. Using a bathroom scale I found that my

the car it will be necessary to lift the motor and its mounts

slightly in order to remove the stock K-member. Before proceeding

with the K-member removal, you will need to remove the stock

struts, spindles, brakes, caster/camber plates, steering rack and

control arms. Take care to avoid injury when removing the front

springs! They are under tremendous pressure and must be handled

carefully and safely. I use a floor jack under the control arm

and with the top strut mount loose slowly lower the floor jack.

This allows the spring to extend to the maximum and then I use a

pry bar to pop it out while standing away from the wheel well

area. Disconnect the tie rods and remove the spindles and don't

forget the sway bar as well. Now you can remove the K-member

bolts (4 per side) and drop the K-member using a floor jack.

Again, be careful, as this piece is heavy. I left my stock

control arms attached to the K-member since I was switching to

the aftermarket units. Using a bathroom scale I found that my

stock stamped steel K-member with factory control arms weighed

79.5 lb. The previously removed power steering rack, pump, and

lines with fluid accounted for another 38 lb. The Eibach drag

launch front springs I removed weighed 10 lb. each. By

comparison, the Unlimited Performance tubular front end and

Flaming River manual rack weighed 29 lb for the K-member, 6 lb

for each control arm, 6 lb for each coilover unit (without strut)

and 11 lb for the manual steering rack. This represents weight

savings of 73.5 lb (stock components add up to 137.5, aftermarket

64 lb). Incidentally, the stock front sway bar weighed in at 24

lb and will be replaced by a lightweight

Steeda unit at 11 lb,

which brings my total weight savings to 86.5 lb.

stock stamped steel K-member with factory control arms weighed

79.5 lb. The previously removed power steering rack, pump, and

lines with fluid accounted for another 38 lb. The Eibach drag

launch front springs I removed weighed 10 lb. each. By

comparison, the Unlimited Performance tubular front end and

Flaming River manual rack weighed 29 lb for the K-member, 6 lb

for each control arm, 6 lb for each coilover unit (without strut)

and 11 lb for the manual steering rack. This represents weight

savings of 73.5 lb (stock components add up to 137.5, aftermarket

64 lb). Incidentally, the stock front sway bar weighed in at 24

lb and will be replaced by a lightweight

Steeda unit at 11 lb,

which brings my total weight savings to 86.5 lb.

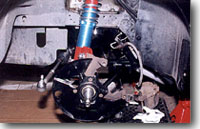

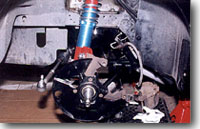

Installation of the tubular K-member was fairly easy. It is so

light that I was able to hold the K-member in place with one hand

as I installed the bolts with the other hand. At this time its

probably not a bad idea to go ahead and check the K-member

alignment using a couple of strings as described in the

"

Mustang Performance Handbook 2 : Chassis and Suspension Modifications for

Street, Drag and Road Racing Use."

by Mathis. This uses known chassis points as well as two K-member

mounting points to take cross measurements. The cross measurements

should be within 1/4". Next, the control arm bushings and sleeves

light that I was able to hold the K-member in place with one hand

as I installed the bolts with the other hand. At this time its

probably not a bad idea to go ahead and check the K-member

alignment using a couple of strings as described in the

"

Mustang Performance Handbook 2 : Chassis and Suspension Modifications for

Street, Drag and Road Racing Use."

by Mathis. This uses known chassis points as well as two K-member

mounting points to take cross measurements. The cross measurements

should be within 1/4". Next, the control arm bushings and sleeves

were installed into the tubular control arms using grease on the

bushings. The control arms took a bit of a struggle to get into

the K-member mounts but the bolts were eventually slid through

and everything stayed in place. I also recommend using a bit of

anti-seize compound on these fasteners as well as the K-member

bolts just in case you need to remove them in the future. The

coilovers were then assembled on the strut but in order to fit

the top mount into the spring, another trip to the machine shop

were installed into the tubular control arms using grease on the

bushings. The control arms took a bit of a struggle to get into

the K-member mounts but the bolts were eventually slid through

and everything stayed in place. I also recommend using a bit of

anti-seize compound on these fasteners as well as the K-member

bolts just in case you need to remove them in the future. The

coilovers were then assembled on the strut but in order to fit

the top mount into the spring, another trip to the machine shop

was required. A press was needed to seat the top mount into the

spring. The now assembled strut/coilover unit was placed on the

bench and attention directed to the caster/camber plates. The

Maximum Motorsports CC plates were then installed on the car and

the factory strut bumper stop eliminated. The spindle was

reattached to the control arm followed by the stut/coilover

assembly being loosely bolted into place. At this time it became

apparent that the coilover could interfere with the factory brake

line mount so this was moved out of the way and will later be

relocated.

was required. A press was needed to seat the top mount into the

spring. The now assembled strut/coilover unit was placed on the

bench and attention directed to the caster/camber plates. The

Maximum Motorsports CC plates were then installed on the car and

the factory strut bumper stop eliminated. The spindle was

reattached to the control arm followed by the stut/coilover

assembly being loosely bolted into place. At this time it became

apparent that the coilover could interfere with the factory brake

line mount so this was moved out of the way and will later be

relocated.

The Flaming River steering components were up next. When

installing the control arms make sure the threaded portion of

the bolt faces the inside (away from the steering rack). This

keeps the fasteners from rubbing on the steering rack boots as

you turn. The manual rack is then slid onto the mounts using

the rack bushings and fasteners as previously mentioned. The

solid steering shaft has a series of setscrews that require a

dimple to be placed prior to final assembly. This will be done

later after my motor is in the car so as to insure no rubbing

on any exhaust components. The u-joints on the solid steering

shaft must be assembled in phase as per the supplied diagram.

the bolt faces the inside (away from the steering rack). This

keeps the fasteners from rubbing on the steering rack boots as

you turn. The manual rack is then slid onto the mounts using

the rack bushings and fasteners as previously mentioned. The

solid steering shaft has a series of setscrews that require a

dimple to be placed prior to final assembly. This will be done

later after my motor is in the car so as to insure no rubbing

on any exhaust components. The u-joints on the solid steering

shaft must be assembled in phase as per the supplied diagram.

Make sure you do not turn the steering wheel excessively in any

one direction while the steering shaft is out because it can

break the factory clock-spring mechanism causing the airbag light

to come on later. Once you have everything where you need it with

the solid steering shaft hooked up, turn the steering wheel from

center to full lock each side and count the turns while a friend

counts the turns on the steering shaft u-joint. You should have

fairly equal turns and if not then the u-joint needs to be turned

accordingly before re-installation on the steering rack.

Make sure you do not turn the steering wheel excessively in any

one direction while the steering shaft is out because it can

break the factory clock-spring mechanism causing the airbag light

to come on later. Once you have everything where you need it with

the solid steering shaft hooked up, turn the steering wheel from

center to full lock each side and count the turns while a friend

counts the turns on the steering shaft u-joint. You should have

fairly equal turns and if not then the u-joint needs to be turned

accordingly before re-installation on the steering rack.

The final steps involve installation of the rotors. Make sure the

wheel bearings are packed with grease and torque the spindle nut

as per your shop manual. Don't forget a new cotter pin then

reinstall the caliper and relocate the brake hose mount to a

location that does not rub anywhere as you check full front

suspension travel and during turns. I used stainless steel

aliper bushing sleeves in place of the factory rubber bushings,

again don't forget the anti-size compound. The car will require a

wheel bearings are packed with grease and torque the spindle nut

as per your shop manual. Don't forget a new cotter pin then

reinstall the caliper and relocate the brake hose mount to a

location that does not rub anywhere as you check full front

suspension travel and during turns. I used stainless steel

aliper bushing sleeves in place of the factory rubber bushings,

again don't forget the anti-size compound. The car will require a

front-end alignment when done. The shaved front-end weight should

help improve both ET at the strip as well as handling. In

addition, there is more room for headers and enhanced oil pan

access. In my case the weight reduction should help offset the

added weight of the intended blower as well as the heavier than

stock cast iron TFS Street Heat heads. The car will get a newly

built blown 302 over the winter therefore driving impressions of

the new front end will have to wait a bit longer.

front-end alignment when done. The shaved front-end weight should

help improve both ET at the strip as well as handling. In

addition, there is more room for headers and enhanced oil pan

access. In my case the weight reduction should help offset the

added weight of the intended blower as well as the heavier than

stock cast iron TFS Street Heat heads. The car will get a newly

built blown 302 over the winter therefore driving impressions of

the new front end will have to wait a bit longer.

Always remember that there is no such thing as a "simple bolt-on".

such I looked at a few different companies before settling on

the kit from

such I looked at a few different companies before settling on

the kit from